I-CNC yokugaya kunye nokujika iyaguquguquka, iyabiza kwaye ichanekile, kodwa amathuba omatshini we-CNC ayanda nangakumbi xa ukugqiba okongeziweyo kuqwalaselwa.Zeziphi iindlela onokukhetha kuzo?Nangona oko kuvakala njengombuzo olula, impendulo intsonkothile kuba zininzi izinto ekufuneka ziqwalaselwe.

Iiprojekthi zePrototype

Okokuqala, yintoni ukugqiba?Ngaba kukuphucula ubuhle okanye ukusebenza?Ukuba le yokugqibela, yeyiphi imiba yokusebenza ekufuneka iphuculwe?Ukunganyangeki kokutya, ukuqina komphezulu, ukumelana nokunxiba okanye ukukhuselwa kwe-EMI/RFI?Le yeminye yemibuzo ekufuneka iphendulwe ke, sicinga ukuba umyili uyazazi iinjongo, makhe sijonge kwiinketho ezahlukeneyo.

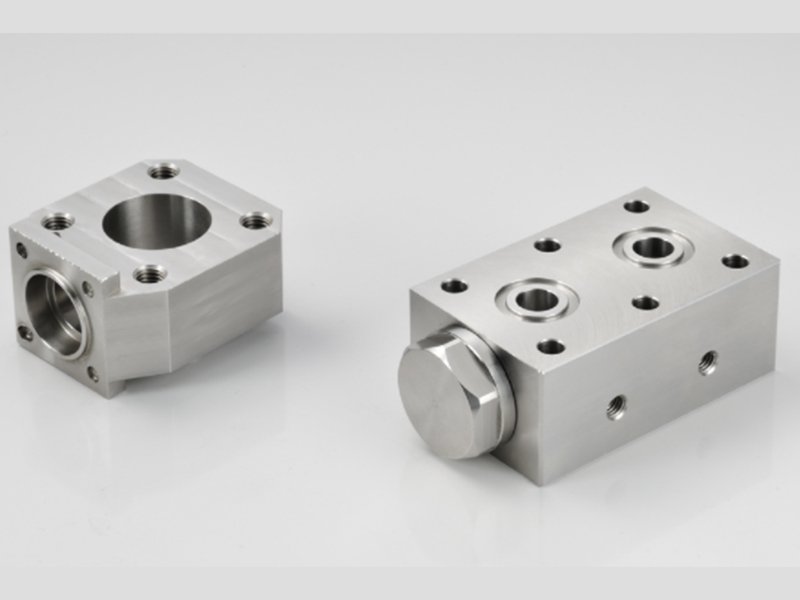

Ukugqiba kwi-CNC Machined Metal Prototype Parts

Kule minyaka ingama-40 idlulileyo, oomatshini bePrototype Projects baceliwe ukuba bavelise iinxalenye kuluhlu olukhulu lwesinyithi ukuze zisetyenziswe kumashishini amaninzi.Iimveliso zihlanjululwa rhoqo, zihlanjululwe kwaye zihlanjululwe, nangona kunjalo, ukhetho lokugqiba lubanzi kakhulu.

Namhlanje, iintsimbi ezithandwa kakhulu ngabathengi bethu ziyi-aluminium alloy 6068, intsimbi engatyiwa 304 kunye nentsimbi engatyiwa 316. Enyanisweni, ezi zintathu zicelwa rhoqo ukuba sibambe izitokhwe zazo ngobukhulu obahlukeneyo ukuhlangabezana neemfuno zeentsuku ezintathu ze-Express CNC. inkonzo yomatshini.

Isaziwa kodwa icaciswe kaninzi lubhedu, ubhedu, ubhedu lwephosphor, intsimbi ethambileyo, intsimbi yesixhobo.Ngamaxesha ngamaxesha, abathengi bacela isinyithi se-sepcial.Ukuba siyakwazi ukufumana imathiriyeli kwaye siyitshise ngaphakathi, siya kuyenza loo nto, kungenjalo sihlala sikhupha umsebenzi kwingcali ekhethwe kuthungelwano lweevenkile ezithembekileyo zoomatshini.Umzekelo, ii-alloys zangaphandle ezifana ne-Inconel, i-Monel kunye ne-Hastelloy zidla ngokufuna ubuchule obuthile kunye nezixhobo zokusebenza, ke sihlala sikhupha oku.

Isinyithi sinokugqitywa ngeendlela ezininzi ezahlukeneyo.Umzekelo, i-aluminiyam ngokubanzi inokucaca i-anodised, i-hardcoat anodised, okanye emnyama okanye i-anodised enombala.Ukhetho luxhomekeke ekubeni imfuno kukuphucula i-aesthetics okanye ukusebenza (ngokukodwa ukuchasana nokugqwala okanye ukuxhatshazwa kokugqoka).

Intsimbi estainless iyakwazi ukumelana nomhlwa kodwa ngamanye amaxesha abathengi bachaza izinto ezongeziweyo.Ngokomzekelo, i-Electropolishing ivelisa umgangatho ophezulu wokugqitywa kunye nokukhupha kunye nokususa imiphetho kwiindawo ezinzima.Ngakolunye uhlangothi, ukuba ubunzima bomphezulu, ukuxhathisa okanye ukukhathala kufuneka kuphuculwe, zombini i-304 kunye ne-316 insimbi engenasici inokuthi i-nitrocarburised okanye i-nitrided.

Iinzuzo zentsimbi ethambileyo ukusuka mhlawumbi kolona khetho lubanzi lokugqitywa.Ukhetho lubandakanya ukupeyinta okumanzi, ukupeyinta kwe-electrophoretic, ukugquma umgubo, ukufakwa kwe-electroplating, ukufakwa kwekhemikhali emnyama, ukufakwa kwe-electropolishing, ukuqina, ukugquma kwe-titanium nitriding (TiN), i-nitrocarburising, kunye nokuqhushumba kweentsimbi, njl.

Ubhedu kunye nobhedu zidla ngokuchazwa kwiindawo ezisebenzayo, ngaphandle kokugqiba okufunekayo emva komatshini.Ukuba kuyimfuneko, nangona kunjalo, iindawo zinokuthi ziphuculwe ngesandla, i-electropolished, i-electroplated, i-vapor blasted, i-lacquered okanye iphathwe nge-chemical blacking.

Ukugqitywa okuchazwe ngasentla akukuphela kwento ekhoyo yesinyithi kunye ne-alloys.Sihlala sonwabile ukuxoxa ngesiphelo kunye nabathengi kwaye sizama ukunceda naphi na apho sinakho.

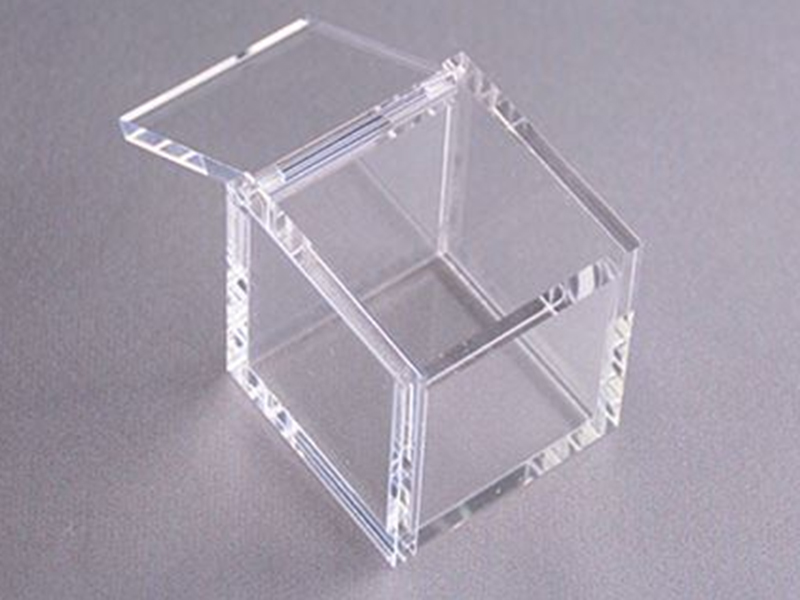

Ukugqiba kwi-CNC Machined Plastic Prototype Parts

Njengakwizahlulo zentsimbi, zonke iinxalenye zeplastiki thina kumatshini we-CNC ngokusisiseko zikhutshiwe, zicociwe kwaye zohlisiwe kodwa, emva koko, ukhetho lomphezulu luthande ukwahluka.

Njengoko uninzi lwabathengi bacela i-CNC yomatshini wokulinganisa iinxalenye zeplastiki nokuba yi-acetal (emnyama okanye yendalo) okanye i-acrylic, sibamba iintlobo ze-acetal.impahla ekhoyo.I-Acetal ayikwamkeli lula ukugqibezela okongeziweyo, ngoko ke iindawo zidla ngokubonelelwa 'njengoomatshini'.

I-Acrylic, ecacileyo, idla ngokugudiswa kwimbonakalo ecacileyo.Oku kunokwenziwa ngesandla ngamabakala acolekileyo ngokulandelelanayo okurhabaxa, okanye ngokukhazimliswa kwedangatye.Ngokwesicelo somntu, i-acrylic inokupeyintwa ngepeyinti ye-acrylic okanye i-vacuum metallised ukufikelela kwindawo ebonakalisa kakhulu.

Ezinye zezi kulula ukuzigqiba kunezinye, ngoko wamkelekile ukuba uxoxe ngemathiriyeli kwaye ugqibe nathi.Ngokumalunga neplastiki, singenza isanti, sipeyinte iinxalenye eziphambili, sizipolishe (ngesandla okanye ngedangatye), ipleyiti engenambane okanye ivacuum metallise.Kwezinye iiplastiki ezinamandla aphantsi komhlaba, ukulungiswa kwengcali yendawo kunye ne-primer okanye unyango lwe-plasma luyimfuneko.

Ukuhlolwa koMda we-CNC Machined Prototype Parts

Isizathu esinye sokuba abathengi bakhethe ukuba neenxalenye ze-CNC ezenziwe ngoomatshini endaweni ye-3D eprintiweyo kukuchaneka okuphezulu.Unyamezelo lwethu olucatshulweyo lwamacandelo omatshini e-CNC yi-±0.1mm, nangona imilinganiselo iqhele ukubanjelwa kukunyamezelana okungqongqo, kuxhomekeke kulwakhiwo, imathiriyeli, kunye nejometri.Siyijonga ngokungqongqo imilinganiselo, ewe, abathengi banokucela iimpawu ezithile ezikhangelweyo.

Rhoqo imilinganiselo inokuthatyathwa ngeefowuni eziphathwa ngesandla okanye ii-micrometers kodwa umatshini wethu wokulinganisa wolungelelwaniso (CMM) ulungele uhlolo olucokisekileyo.Oku kuthatha ixesha kwaye akufumaneki ngenkonzo yethu ye-CNC ephezulu kodwa ikhawuleza kunokuthumela iinxalenye kumntu wesithathu ukuze kuhlolwe i-CMM.Ekuphela kwezinto ezinxaxhileyo kuxa inkqubo yokuhlola i-CMM ebanzi, ecwangciswe ngokupheleleyo ifuneka, okanye ibhetshi yamacandelo yenziwe ngoomatshini kwaye kufuneka i-100 leepesenti ihlolwe.

Iinketho zeNdibano zeCNC Machined Prototype Parts

Esinye isizathu kukuba abathengi bakhethe ukuba neenxalenye zeprototype ze-CNC ezenziwe ngoomatshini kunokuba i-3D iprintwe kukuchaneka okuphezulu.Unyamezelo oluvumelekileyo lweendawo zoomatshini be-CNC yi-±0.1mm, nangona imilinganiselo iqhele ukubanjelwa kukunyamezelana okungqongqo, ngokuxhomekeke kwimathiriyeli kunye nejometri.Siza kuhlola ngokungqongqo zonke iindawo phambi kokuba zithunyelwe, kwaye abathengi banokucela iimpawu ezithile ukuba zihlolwe ngokunjalo.

Rhoqo imilinganiselo inokuthatyathwa ngeefowuni eziphathwa ngesandla okanye ii-micrometers kodwa umatshini wethu wokulinganisa wolungelelwaniso (CMM) ulungele uhlolo olucokisekileyo.Kuyakhawuleza kunokuthumela iinxalenye kumntu wesithathu ukuze kuhlolwe iCMM.Ekuphela kwezinto ezinxaxhileyo kuxa inkqubo yokuhlola i-CMM ebanzi, ecwangciswe ngokupheleleyo ifuneka, okanye ibhetshi yamacandelo yenziwe ngoomatshini kwaye kufuneka i-100 leepesenti ihlolwe.

Ixesha lokuposa: Jun-30-2022